-

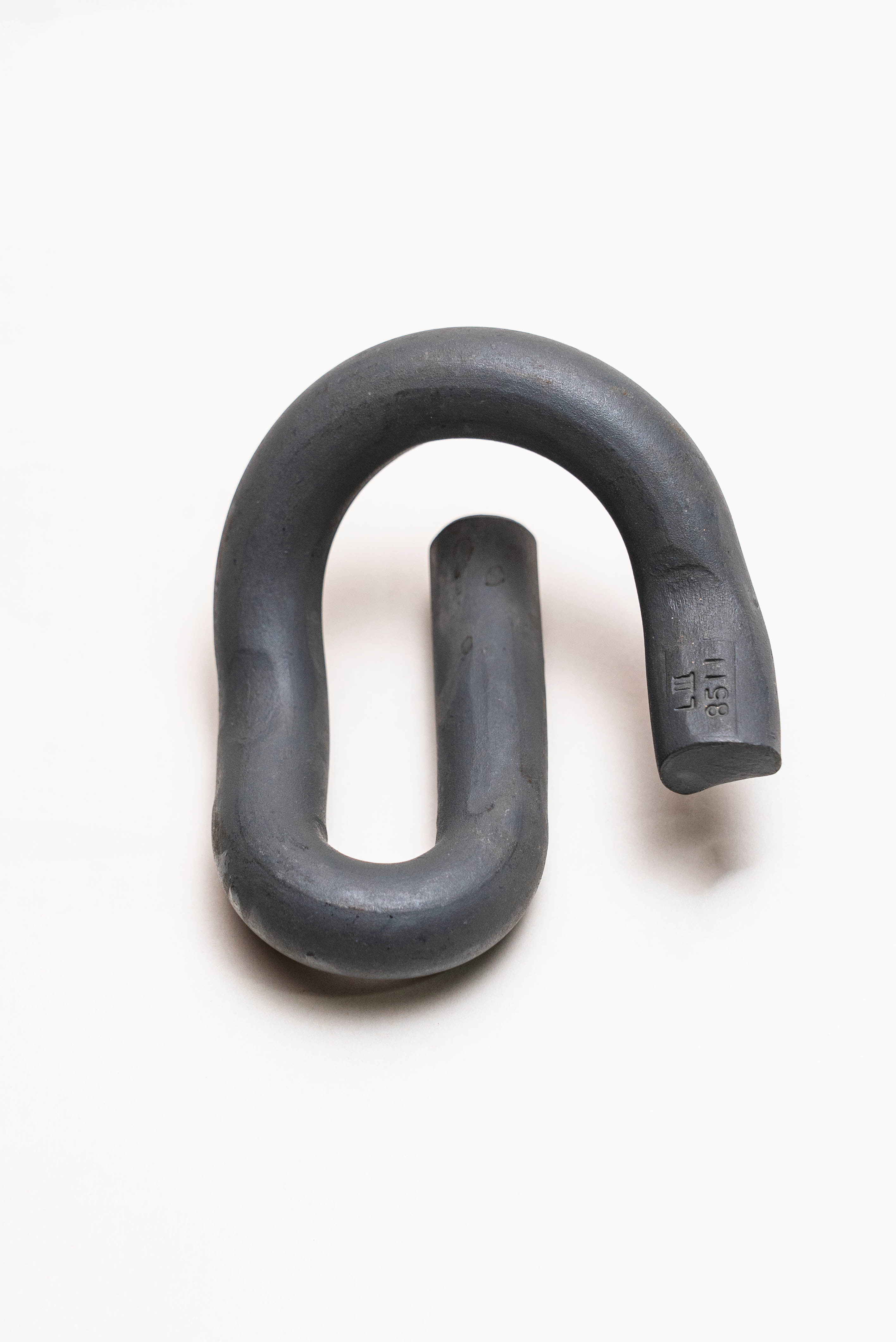

ProductsAt present, the company has the ability to produce 50000 tons of rail buckle accessories annually. The product series includes various specifications of spring bars Gauge baffles, switch special pads, joint clamps for 43kg, 50kg, 60kg steel rails, various export products, etc

-

-

AboutThe company was established in 1994 and is a production enterprise specializing in the research and development, production, and sales of railway line specific accessories

Understanding Rail Track Spikes: Key Components for Transportation Safety

Apr 25,2025

Rail track spikes, also known as railroad spikes, are essential components in the construction and maintenance of railway tracks. Their primary function is to secure the rail to the sleeper (or tie), ensuring that the rails remain aligned and stable under the weight of passing trains. The reliability of rail track spikes directly influences the overall safety and efficiency of rail transportation,

Typically made from steel, rail track spikes come in various designs to accommodate different types of rail systems and track configurations. The most common spike type is the cut spike, which features a tapered point for easy insertion into wooden or concrete ties. Other designs include the screw spike, which provides enhanced stability through a threaded mechanism, and the welded rail spike, which is used for bolted rail connections. The choice among these types depends on factors such as the type of rail, the load it will bear, and environmental conditions.

One of the essential aspects of rail track spikes is their installation. Proper installation is crucial to ensure the longevity and effectiveness of the spikes. Incorrectly installed spikes can lead to misalignment of the rails, potentially causing derailments and compromising the safety of train operations. To mitigate these risks, it is vital to follow best practices during the installation process, including using the correct spike type for the specific rail and ensuring that spikes are driven in at the appropriate angle and depth.

Maintenance is another pivotal aspect of rail track spike management. Regular inspections should be conducted to assess the condition of the spikes and the surrounding track infrastructure. Signs of wear, corrosion, or loosening should be addressed promptly to avoid catastrophic failures. In addition, it's essential to monitor the integrity of the ties, as degraded ties can lead to increased stress on the spikes, further exacerbating wear and tear.

In conclusion, rail track spikes serve as a fundamental element in the railway infrastructure, directly impacting the safety and reliability of rail transport. Understanding the types, functions, and maintenance requirements of these components is crucial for professionals in the automotive and transportation safety equipment sectors. By prioritizing proper installation and routine maintenance of rail track spikes, we can ensure a safer and more efficient railway system for future generations. In doing so, we reinforce the integrity of our transportation networks, promoting seamless connectivity across regions.

Previous:

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us

Henan Xinda Railway Equipment Co., Ltd

Fax: +86-372-2615999

Tel: +86-18567891234

Email:info@xindarail.com

Send us your request

we will get in touch with you as soon as possible

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.