Understanding the Regulatory Standards for Rail Elastomer Usage: A Comprehensive Guide

Aug 20,2025

Understanding the Regulatory Standards for Rail Elastomer Usage Table of Contents 1. Introduction to Rail Elastomers 2. Importance of Regulatory Standards in Rail Elastomer Usage 3. Key Regulatory Bodies Involved 4. Material Specifications and Performance Standards 5. Safety Standards for Rail Elastomers 6. Environmental Considerations 7. Challenges in Compliance with

Understanding the Regulatory Standards for Rail Elastomer Usage

Table of Contents

- 1. Introduction to Rail Elastomers

- 2. Importance of Regulatory Standards in Rail Elastomer Usage

- 3. Key Regulatory Bodies Involved

- 4. Material Specifications and Performance Standards

- 5. Safety Standards for Rail Elastomers

- 6. Environmental Considerations

- 7. Challenges in Compliance with Regulatory Standards

- 8. Future Trends in Rail Elastomer Regulations

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to Rail Elastomers

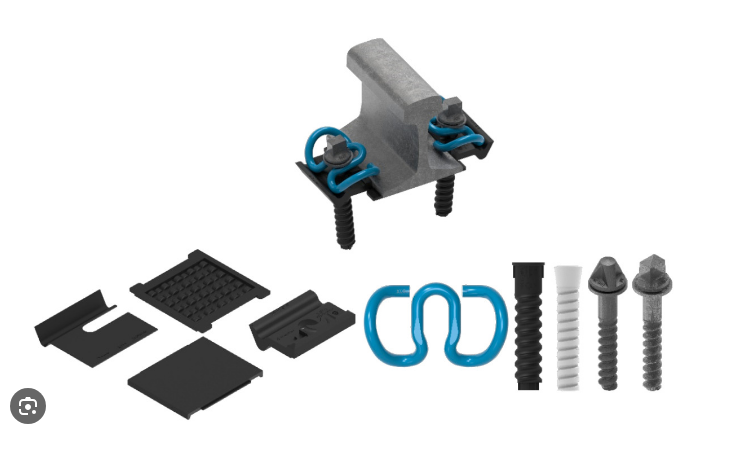

Rail elastomers play a crucial role in the operation and efficiency of rail transportation systems. These flexible materials are essential for various components, including seals, gaskets, and vibration dampers, ensuring the performance of trains and tracks under demanding conditions. The utilization of elastomers in rail systems must adhere to stringent regulatory standards to guarantee safety, reliability, and environmental sustainability.

2. Importance of Regulatory Standards in Rail Elastomer Usage

Regulatory standards for rail elastomers are vital for several reasons. They ensure:

- **Safety**: Standards protect both passengers and freight by minimizing risks associated with material failure.

- **Performance**: Adhering to specifications allows for optimal performance of rail components, enhancing operational efficiency.

- **Environmental Protection**: Regulations aim to reduce the environmental impact of materials used in rail systems, promoting sustainability.

Understanding these regulations is essential for manufacturers, engineers, and regulatory bodies to ensure compliance and maintain high-quality standards.

3. Key Regulatory Bodies Involved

Several organizations oversee the regulatory landscape for rail elastomers, including:

- **Federal Railroad Administration (FRA)**: In the United States, the FRA is responsible for enforcing safety regulations and conducting audits on rail systems.

- **American Society for Testing and Materials (ASTM)**: This organization develops and publishes technical standards for materials used in various industries, including rail.

- **International Organization for Standardization (ISO)**: ISO develops international standards, which include guidelines for elastomer materials in rail applications.

These bodies work together to create a framework that ensures the safe use of elastomers in rail systems.

4. Material Specifications and Performance Standards

The performance of rail elastomers is dictated by specific material specifications that highlight crucial factors such as:

- **Temperature Resistance**: The ability of elastomers to withstand extreme temperatures is essential for maintaining integrity under varying climatic conditions.

- **Chemical Resistance**: Elastomers must resist degradation from oils, fuels, and other chemicals encountered in rail environments.

- **Mechanical Properties**: Specifications regarding tensile strength, elongation, and hardness are critical to ensure that the elastomers can withstand the mechanical stresses of rail operations.

Compliance with these material specifications is crucial for manufacturers to deliver safe and reliable products.

5. Safety Standards for Rail Elastomers

Safety is paramount in the rail industry. As such, there are several safety standards that rail elastomers must meet, including:

- **Fire Resistance**: Materials must be tested for flammability and smoke emissions to ensure they do not pose a hazard during incidents.

- **Durability Testing**: Continuous exposure to environmental stressors must be simulated to assess the lifespan and performance under real-world conditions.

- **Impact Resistance**: Elastomers need to be resilient against impacts from rail operations, ensuring that they maintain functionality even during unforeseen circumstances.

Meeting these safety standards is non-negotiable for manufacturers and plays a significant role in the overall safety of rail systems.

6. Environmental Considerations

The environmental impact of rail elastomers cannot be overlooked. Regulations are increasingly focused on sustainability, which includes:

- **Recyclability**: Manufacturers are encouraged to produce elastomers that can be recycled or repurposed at the end of their life cycle.

- **Reduction of Harmful Emissions**: Compliance with laws aimed at reducing VOC (volatile organic compound) emissions is essential for protecting air quality.

- **Use of Sustainable Materials**: Incorporating bio-based or recycled materials into elastomer formulations is becoming a significant focus to minimize environmental footprints.

Adhering to these environmental regulations will not only improve compliance but also enhance the reputation of manufacturers in the industry.

7. Challenges in Compliance with Regulatory Standards

While regulatory standards are designed to ensure safety and quality, manufacturers face several challenges, including:

- **Keeping Up with Changing Regulations**: The regulatory landscape is dynamic, and staying informed about updates can be overwhelming for manufacturers.

- **Cost Implications**: Complying with stringent standards often requires investment in new technologies, testing, and certification processes, which can strain budgets.

- **Limited Knowledge and Resources**: Smaller manufacturers may lack the expertise or resources to meet complex regulatory requirements.

Addressing these challenges requires collaboration between manufacturers, regulatory bodies, and industry stakeholders.

8. Future Trends in Rail Elastomer Regulations

As the rail industry evolves, so too does the landscape of regulations surrounding elastomer usage. Key trends include:

- **Increased Focus on Sustainability**: Future regulations will likely emphasize environmentally friendly materials and practices.

- **Integration of Advanced Technologies**: Technologies such as AI and IoT will enable better monitoring and testing of elastomer performance in real-time.

- **Global Standardization**: As rail systems globalize, there will be a push towards harmonizing regulations across countries to facilitate international trade and compliance.

Staying ahead of these trends is crucial for manufacturers aiming to maintain a competitive edge in the rail elastomer market.

9. Conclusion

Understanding the regulatory standards for rail elastomer usage is essential for ensuring safety, performance, and environmental compliance in rail transportation. By adhering to the guidelines set forth by key regulatory bodies and staying informed about emerging trends, manufacturers can improve their products and contribute to a safer, more efficient rail system. The future of rail elastomers lies in a commitment to sustainability, innovation, and collaboration among all stakeholders in the industry.

10. Frequently Asked Questions

What are rail elastomers?

Rail elastomers are flexible materials used in various components of rail systems, including seals, gaskets, and vibration dampers.

Why are regulatory standards important for rail elastomers?

Regulatory standards ensure the safety, performance, and environmental sustainability of rail elastomers, protecting both passengers and freight.

What regulatory bodies govern rail elastomer usage?

Key regulatory bodies include the Federal Railroad Administration (FRA), American Society for Testing and Materials (ASTM), and the International Organization for Standardization (ISO).

What challenges do manufacturers face in complying with regulations?

Manufacturers may struggle with keeping up with changing regulations, the costs associated with compliance, and limited knowledge of requirements.

What future trends should manufacturers be aware of?

Future trends include a greater emphasis on sustainability, the integration of advanced monitoring technologies, and the push for global standardization of regulations.

This comprehensive article provides a detailed exploration of the regulatory standards for rail elastomer usage, addressing crucial aspects that manufacturers and stakeholders in the rail industry must understand.

Previous:

Recommended

Asia Pacific Rail 2025 Concludes in Bangkok, Showcasing Rail Industry's Future

Bangkok, May 29 - The Asia Pacific Rail 2025, a leading event in the railway and rail transit industry, successfully concluded on May 29 in Bangkok, Thailand.

Contact Us