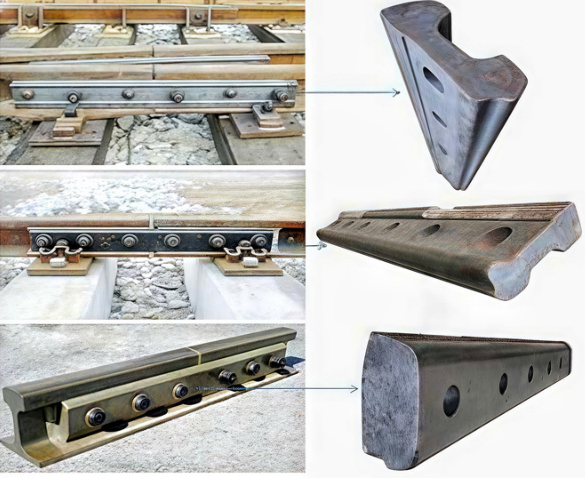

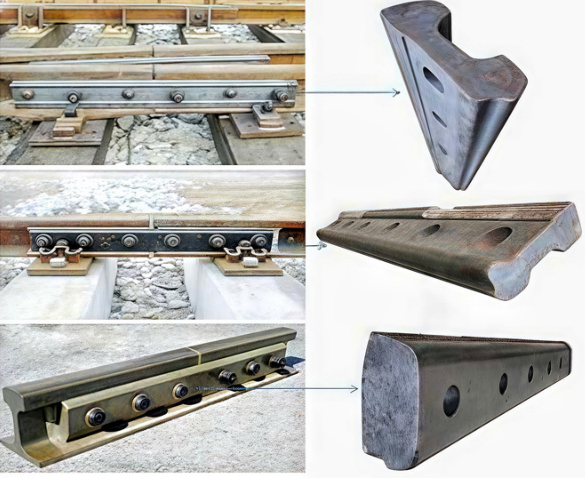

Rail Fish Plate

Jul 02,2025

A key advantage of contemporary designs is their adaptability to various rail profiles, including UIC, ASCE, and BS standards. This versatility makes them indispensable for infrastructure projects, from urban metro systems to cross-country freight lines. Installation is streamlined through pre-drilled bolt holes, reducing assembly time while maintaining uniform clamping force. Some advanced variants even incorporate fatigue-resistant alloys, capable of enduring millions of load cycles without structural compromise.

Xinda has its own production workshop. There is one fishplate punching heat treatment production line, one set of shock-absorbing fishplate production line, and 4 presses of various types. The main products include ordinary fishplates for 43Kg-75Kg rails, insulating fishplates, bulging fishplates, shock-absorbing fishplates, large export fishplates, adjustable fishplates and other series. It has an annual production capacity of 1.56 million fishplates.

The production line uses China's most advanced natural gas heating furnace for fishplates. The heating furnace has good insulation effect and stable product quality and performance. It is qualified in random inspections by the Ministry of Railways every year and is designated as a first-level supplier. In particular, the high-strength buffer fishplate developed by China Railway Design Institute is designated as a designated production unit. At present, the products are exported to the United States, Africa, Vietnam, and other countries.

Xinda has the capability to manufacture all types of rail fishplates to suit all types of rail sections such as UIC 60, UIC 54, U33, BS 80A, BS 90A, IRS 52 KG, IRS 90 Lbs, 115 RE, 136 RE, TJ 45, TJ 37, RN 45, etc. The rail fishplate size can be customized according to the drawings provided by customers.

Fishplate Material

- Ductile Iron

- Rolling

- Forging, etc.

Fishplate Model

The model of fishplate joint can be divided into 8 kg, 12 kg, 15 kg, 18 kg, 22 kg, 24 kg, 30 kg, 38 kg, 43 kg, 50 kg, 60 kg, 75 kg, etc. according to the weight of the rail.

These include:

- Light rail includes 8 kg, 12 kg, 15 kg, 18 kg, 22 kg, 24 kg, 30 kg; light rail fish plate is also known as track splint;

- Heavy rail includes 38 kg, 43 kg, 50 kg, 60 kg; heavy rail fish plate is also known as crane rail bevel joint splint;

- Crane rail has QU70, QU80, QU100, QU120, etc.

- Fishplates also have various international standards such as BS 47 and UIC series such as BS 80A, BS 75R, UIC 60, UIC 54, etc.

Hot Sale Fish Plate From Xinda

Standard | Type | Length/Diameter | Weight /Material | |

AREMA 2007 | 115RE | 4 hole-24" | 17.04Kg | 45# chemical |

| 115RE | 6 hole-36" | 25.56Kg | composition(%): |

| 132-136RE | 4 hole-24" | 17.75Kg | C: 0.42-0.50 |

| 132-136RE | 6 hole-36" | 26.63Kg | Mn: 0.50-0.80 |

UIC864 | UIC60 | 4 hole-630/Φ26 | 18.07Kg | Si: 0.17-0.37 |

| UIC60 | 4 hole-600/Φ28 | 17.47Kg | Cr: ≤0.25 |

| UIC60 | 4 hole-630/Φ25 | 18.1Kg | P: ≤0.035 |

| UIC54 | 4 hole | 14.34Kg | S: ≤0.035 |

| UIC54 | 6 hole-800 | 19.94Kg |

|

BS 47-1 | BS75R | 4 hole | 6.56Kg |

|

| BS60A | 4 hole | 5.61Kg |

|

| BS80A | 4 hole | 6.5Kg |

|

| BS90A | 685.8/Φ26 | 13.23Kg | 50# chemical |

| BS90A | 792.9/Φ26.2 | 15.34Kg | composition(%): |

| BS100A | 4 hole |

| C: 0.62-0.70 |

| 90/91LB | 4 hole | 18.08Kg | Mn: 0.50-0.80 |

| 90/91LB | 6 hole | 19.9Kg | Si: 0.17-0.37 |

AS | 50kg | 4 hole | 14.3Kg | Cr: ≤0.25 |

| 50kg | 6 hole | 19.5Kg | P: ≤0.035 |

| S49 | 4 hole | 9.71Kg | S: ≤0.035 |

Rail Fish Plate:A key advantage of contemporary designs is their adaptability to various rail profiles, including UIC, ASCE, and BS standards. This versatility makes them indispensable for infrastructure projects, from urban metro systems to cross-country freight lines. Installation is streamlined through pre-drilled bolt holes, reducing assembly time while maintaining uniform clamping force. Some advanced variants even incorporate fatigue-resistant alloys, capable of enduring millions of load cycles without structural compromise.

In high-traffic zones, these components mitigate the risk of rail fractures by evenly dispersing mechanical stress. Their robust construction also reduces maintenance frequency, cutting downtime and operational costs for rail operators. Innovations like laser-etched identification marks enable easy traceability, ensuring compliance with stringent transportation safety regulations.

As railways embrace heavier loads and faster speeds, the evolution of fish plate technology underscores its critical role in modern transit systems. By enhancing durability, ease of installation, and performance under stress, these unassuming yet vital connectors are driving the future of rail infrastructure—one secure joint at a time.

Recommended

Asia Pacific Rail 2025 Concludes in Bangkok, Showcasing Rail Industry's Future

Bangkok, May 29 - The Asia Pacific Rail 2025, a leading event in the railway and rail transit industry, successfully concluded on May 29 in Bangkok, Thailand.

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Contact Us