System 300 W Elastic. Safe. Resilient. Flexible. Remark: Contents, figures and technical data in this brochure display the performance of the fastening system, however, they always depend on external conditions. Please contact us to enable us to develop a solution for you that will be customized to your requirements. The information presented corresponds to the technical state at the time of printing; in the meantime, continuous research and development programmes at Xinda rail could cause adaptations of the product.

Remark: Contents, figures and technical data in this brochure display the performance of the fastening system, however, they always depend on external conditions. Please contact us to enable us to develop a solution for you that will be customized to your requirements.

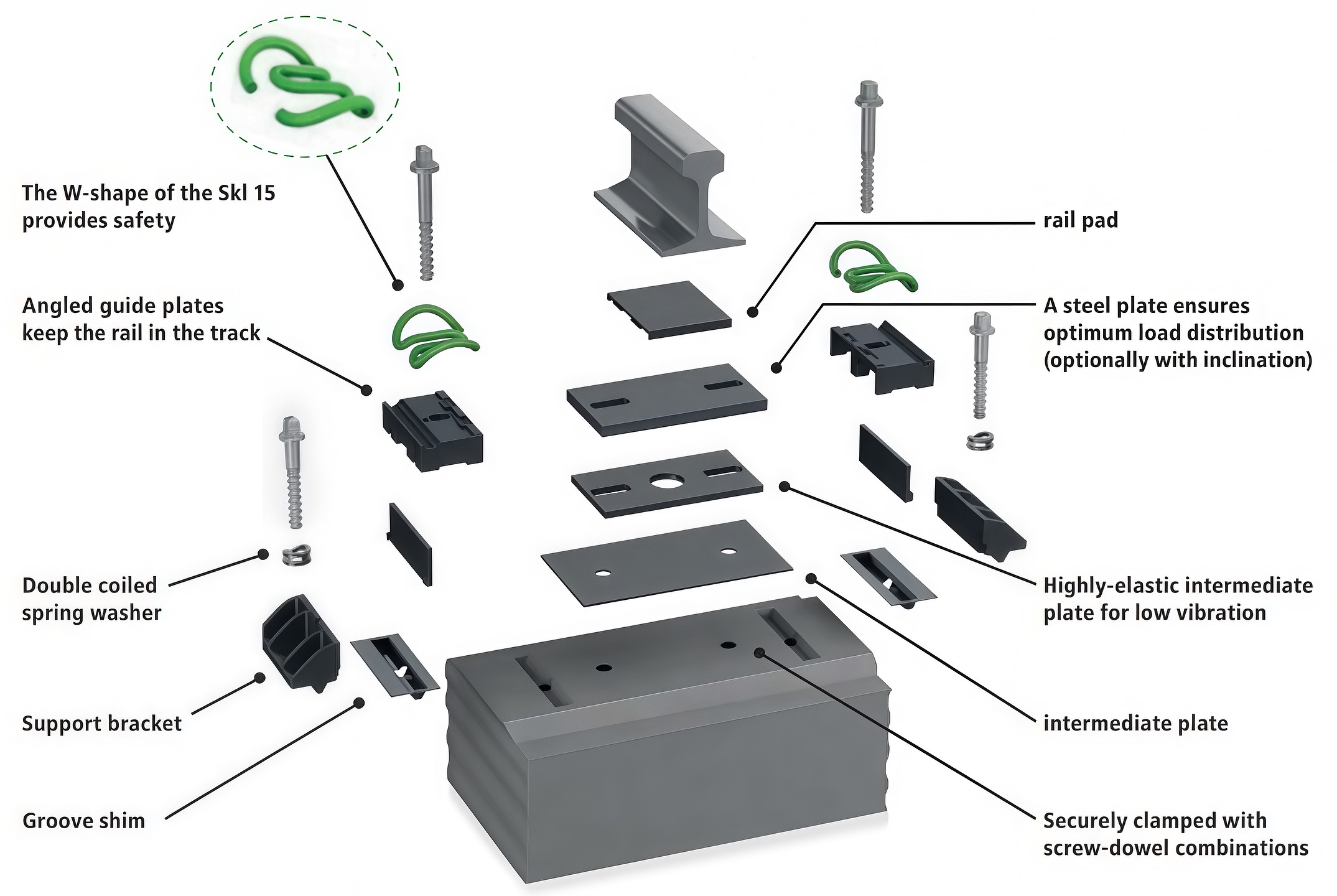

The rail fastening system typically consists of several key components. One of the main parts is the fastening clip, which grips the rail base and holds it firmly to the sleeper or tie. These clips are often made of high - strength steel and are designed to withstand the dynamic loads exerted by passing trains. Another important component is the baseplate, which provides a stable connection between the rail and the sleeper. The baseplate distributes the load from the rail over a larger area of the sleeper, reducing the pressure on the underlying structure. Additionally, there are insulating elements in many fastening systems. In electrified railway lines, these insulators prevent the flow of electric current from the rail to the sleeper, ensuring the safety of the trackside equipment and personnel.

The primary function of the rail fastening system is to keep the rails in the correct position both longitudinally and laterally. This is vital for maintaining the proper gauge of the track, which is the distance between the two rails. A consistent gauge is necessary for the smooth running of trains, as any deviation can cause derailment or excessive wear on the wheels and rails. The fastening system also helps to absorb and dampen the vibrations generated by the moving trains. By doing so, it reduces the transmission of these vibrations to the surrounding soil and structures, minimizing the potential for damage. Moreover, in high - speed railway lines, the fastening system needs to be able to resist the high - frequency dynamic loads and ensure the stability of the rails at high speeds.

W300 Rail Fastening System

Contact

Classification

Product Inquiry

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible