Innovative Applications of Rail Elastomers in Modern Rail Transport

Apr 27,2025

Rail elastomers are specialized materials used in rail transport systems to provide damping and vibration isolation. These elastomeric components play a crucial role in enhancing the overall performance and lifespan of rail infrastructure. Understanding their properties and applications is vital for professionals in the rail transport industry. One of the primary functions of rail elastomers is to

One of the primary functions of rail elastomers is to absorb shocks and vibrations generated by the movement of trains. This is particularly important in urban areas where noise pollution and comfort are significant concerns for both passengers and residents. Rail elastomers, typically made from synthetic rubber compounds, are engineered to provide excellent energy absorption characteristics. By minimizing the transmission of vibrations to the rail structure and surrounding environment, these materials contribute to quieter and more comfortable rides.

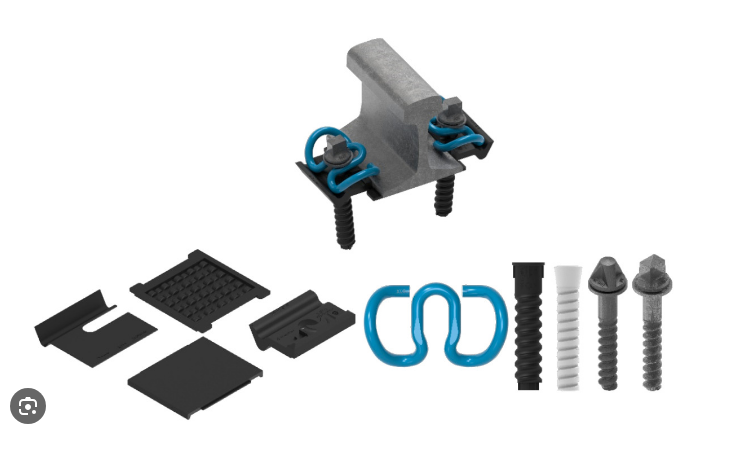

In addition to noise reduction, rail elastomers also contribute to the overall safety and reliability of rail systems. They are often used in applications such as rail fastening systems, where they secure the rail to the sleeper while allowing for some flexibility. This flexibility is essential as it accommodates thermal expansions and contractions, preventing rail buckling and ensuring the integrity of the track. Moreover, the use of rail elastomers can reduce wear and tear on both trains and tracks, leading to lower maintenance costs and extended service life for the infrastructure.

Another significant advantage of rail elastomers is their ability to improve ride quality. By effectively damping vibrations, these materials enhance passenger comfort, making journeys smoother and more enjoyable. This is especially important as rail transport competes with other modes of transportation. A comfortable ride can result in increased ridership and better customer satisfaction.

When considering the implementation of rail elastomers, it is essential to select the appropriate type based on the specific requirements of the rail system. Factors such as load-bearing capacity, environmental conditions, and required durability must be taken into account. Custom formulations of elastomers can be developed to meet the unique challenges faced by different rail applications, ensuring optimal performance.

In conclusion, rail elastomers are indispensable in modern rail transport systems. Their ability to provide vibration isolation, enhance safety, and improve passenger comfort makes them a valuable component of rail infrastructure. As the rail industry continues to evolve, the innovation and application of rail elastomers will remain integral to achieving efficient and sustainable transport solutions. By investing in the right materials and technologies, stakeholders in the rail transport sector can ensure that they meet the growing demands of urban mobility while maintaining operational excellence.

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us