Cost Savings and Efficiency: The Economic Benefits of Rail Elastomers

Apr 28,2025

Cost Savings and Efficiency: The Economic Benefits of Rail Elastomers Table of Contents 1. Introduction to Rail Elastomers 2. What Are Rail Elastomers? 3. Economic Benefits of Rail Elastomers 3.1 Cost Savings Through Longevity 3.2 Efficiency Improvements in Maintenance 3.3 Operational Efficiency in Rail Systems 4. Applications

Cost Savings and Efficiency: The Economic Benefits of Rail Elastomers

Table of Contents

- 1. Introduction to Rail Elastomers

- 2. What Are Rail Elastomers?

- 3. Economic Benefits of Rail Elastomers

- 3.1 Cost Savings Through Longevity

- 3.2 Efficiency Improvements in Maintenance

- 3.3 Operational Efficiency in Rail Systems

- 4. Applications of Rail Elastomers

- 5. The Future of Rail Elastomers in Transportation

- 6. Challenges and Solutions in Rail Elastomer Adoption

- 7. Conclusion

- 8. Frequently Asked Questions

1. Introduction to Rail Elastomers

In the ever-evolving landscape of transportation, rail systems have increasingly turned towards innovative materials to enhance performance. One such material that has garnered attention is **rail elastomers**. These versatile components play a pivotal role in ensuring the efficiency and cost-effectiveness of rail transportation. This article delves into the economic benefits of rail elastomers, highlighting their role in cost savings and operational efficiency.

2. What Are Rail Elastomers?

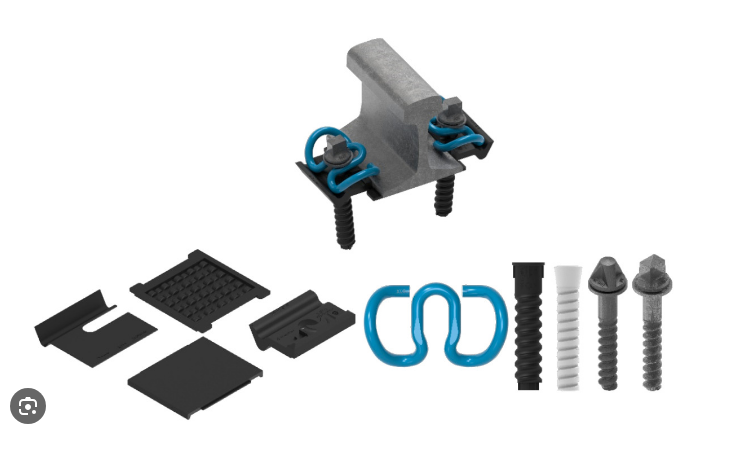

Rail elastomers are specialized rubber materials designed to meet the demanding requirements of rail transport systems. They are engineered for durability, resilience, and optimal performance under various conditions. Commonly used in components such as **track pads**, **vibration dampers**, and **seals**, rail elastomers are integral to maintaining the integrity and reliability of rail operations.

The properties of rail elastomers include:

- **High elasticity**: Allowing them to absorb vibrations and shocks effectively.

- **Weather resistance**: Ensuring longevity despite exposure to environmental elements.

- **Durability**: Capable of withstanding heavy loads and continuous wear.

3. Economic Benefits of Rail Elastomers

The economic implications of adopting rail elastomers in transport systems are profound. By utilizing these materials, rail companies can achieve remarkable cost savings and efficiency improvements.

3.1 Cost Savings Through Longevity

One of the primary benefits of rail elastomers is their **extended lifespan** compared to traditional materials. Rail elastomers can significantly reduce the frequency and costs associated with replacements and repairs.

For instance, rail pads made from elastomers can last up to 50% longer than those made from conventional materials. This longevity translates into:

- **Lower maintenance costs**: Less frequent repairs and replacements lead to reduced operational expenses.

- **Increased asset utilization**: With fewer disruptions, rail services can operate more efficiently.

3.2 Efficiency Improvements in Maintenance

Maintenance is a critical aspect of rail operations. Rail elastomers contribute to enhanced maintenance efficiency in several ways:

- **Reduced downtime**: The durability of rail elastomers means that maintenance activities are less frequent, allowing trains to spend more time in service.

- **Simplified maintenance procedures**: The inherent properties of elastomers can make inspections and repairs quicker and easier, further minimizing service interruptions.

3.3 Operational Efficiency in Rail Systems

Operational efficiency is paramount in rail transport, and rail elastomers play an essential role in enhancing this aspect. Their ability to absorb vibrations leads to smoother rides, which benefits both passengers and freight transportation.

Additionally, smoother operations reduce wear and tear on other components of the rail system, leading to:

- **Lower energy consumption**: Efficient operation means that less energy is required to maintain speeds, resulting in reduced fuel costs.

- **Increased rider comfort**: Passengers benefit from a smoother ride, which can enhance customer satisfaction and potentially increase ridership.

4. Applications of Rail Elastomers

Rail elastomers find various applications within the rail transport sector, each contributing to the overall efficiency and cost-effectiveness of rail systems.

4.1 Track Components

Rail elastomers are commonly used in track components, including pads and bearings, to mitigate vibrations and reduce noise. The implementation of elastomeric pads under rail tracks can lead to:

- **Improved track stability**: Enhancing the longevity of the tracks and surrounding infrastructure.

- **Noise reduction**: Leading to more environmentally friendly rail operations, which can be a critical factor in urban areas.

4.2 Vibration Dampeners

Vibration dampeners made from rail elastomers are crucial for minimizing the impact of vibrations on trains and tracks. These dampeners help to:

- **Protect rail infrastructure**: Reducing the stress on bridges and tunnels.

- **Enhance passenger experience**: Leading to a more comfortable ride.

4.3 Train Seals

Seals made from elastomers are vital for ensuring that trains remain airtight and watertight. This is especially important in maintaining the integrity of sensitive systems onboard. Benefits include:

- **Reduced maintenance costs**: By preventing leaks, elastomer seals help avoid costly repairs.

- **Enhanced safety**: Maintaining air quality and safety within train compartments is paramount.

5. The Future of Rail Elastomers in Transportation

As the rail industry continues to evolve, the future of rail elastomers looks promising. Innovations in material science are leading to the development of even more advanced elastomers, which could offer enhanced performance and sustainability.

Future trends may include:

- **Smart materials**: Incorporating sensors into elastomers to monitor performance and wear in real time.

- **Sustainable practices**: Developing eco-friendly elastomers that can reduce environmental impact.

6. Challenges and Solutions in Rail Elastomer Adoption

While the advantages of rail elastomers are clear, challenges regarding their adoption persist. Key challenges include:

- **Initial cost**: The upfront investment in high-quality elastomers can be significant.

- **Market acceptance**: Some rail operators may be hesitant to transition from traditional materials.

Solutions include:

- **Offering financial incentives**: Governments and industry bodies can provide subsidies to encourage the adoption of rail elastomers.

- **Education and training**: Providing information on the long-term benefits of elastomers can help sway decision-makers.

7. Conclusion

In conclusion, rail elastomers represent a significant advancement in the rail transportation industry, providing extensive **economic benefits** through cost savings and operational efficiency. Their durability, versatility, and adaptability make them a valuable asset in modern rail systems. Investing in rail elastomers not only enhances the performance of rail operations but also supports the broader goals of sustainability and innovation in transportation.

8. Frequently Asked Questions

What are rail elastomers?

Rail elastomers are specialized rubber materials designed for use in rail systems, known for their durability and elasticity.

How do rail elastomers provide cost savings?

They offer cost savings by extending the lifespan of components and reducing maintenance frequency, leading to lower operational expenses.

What applications do rail elastomers have in rail transport?

They are used in track components, vibration dampeners, and seals, contributing to overall efficiency and safety.

What challenges exist in implementing rail elastomers?

Challenges include initial costs and market acceptance, which can be mitigated through incentives and education.

What does the future hold for rail elastomers?

The future may see advancements in smart materials and sustainable production practices, further enhancing their benefits in rail transport.

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us