The Evolution of Rail Track Spikes: From Past to Present

May 18,2025

The Evolution of Rail Track Spikes: From Past to Present Table of Contents 1. Introduction to Rail Track Spikes 2. The Historical Significance of Rail Track Spikes 3. Materials Used in Rail Track Spikes: A Comparative Analysis 4. Evolution of Designs: Traditional vs. Modern Rail Track Spikes 5. The Role of Rail Track Spikes in Transportation Safety 6. Manufacturing Process

The Evolution of Rail Track Spikes: From Past to Present

Table of Contents

- 1. Introduction to Rail Track Spikes

- 2. The Historical Significance of Rail Track Spikes

- 3. Materials Used in Rail Track Spikes: A Comparative Analysis

- 4. Evolution of Designs: Traditional vs. Modern Rail Track Spikes

- 5. The Role of Rail Track Spikes in Transportation Safety

- 6. Manufacturing Processes: How Rail Track Spikes are Made

- 7. The Future of Rail Track Spikes: Innovations and Trends

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Rail Track Spikes

Rail track spikes, often considered the unsung heroes of the railway infrastructure, play a crucial role in maintaining the integrity of rail systems. These metal fasteners secure rails to wooden or concrete ties, ensuring stability and safety for trains traveling at high speeds. Understanding the evolution of rail track spikes provides valuable insights into railway technology, safety practices, and material science.

2. The Historical Significance of Rail Track Spikes

The history of rail track spikes dates back to the early days of rail transport in the 19th century. Initially, spikes were made of wrought iron and were crafted by blacksmiths who hand-forged them for local railways. These early spikes were simple in design but crucial for the stability of the tracks.

As railroads expanded, the demand for more durable and efficient fastening systems led to innovations in both the materials and designs of rail spikes. The introduction of steel in the 20th century marked a significant turning point, as it offered increased strength and longevity compared to its wrought iron predecessors.

The transition from wooden ties to concrete sleepers further influenced spike design, requiring manufacturers to adapt their products for enhanced performance under various environmental conditions.

3. Materials Used in Rail Track Spikes: A Comparative Analysis

Today, rail track spikes are typically made from a variety of materials, each offering distinct advantages depending on the application.

3.1 Wrought Iron

Historically the most common material, wrought iron has excellent malleability and resistance to fatigue. However, it is less durable than modern alternatives.

3.2 Steel

Steel, particularly high-carbon steel, is now the material of choice for rail track spikes. It provides superior strength and durability, essential for withstanding the immense forces exerted by trains.

3.3 Stainless Steel

In environments prone to corrosion, stainless steel spikes are preferred due to their resistance to rust and degradation, ensuring a longer lifespan.

3.4 Composite Materials

Emerging technologies have introduced composite materials that combine the benefits of different substances, offering potential for reduced weight and enhanced performance.

4. Evolution of Designs: Traditional vs. Modern Rail Track Spikes

Design innovations have significantly impacted the effectiveness of rail track spikes.

4.1 Traditional Spike Designs

Traditional rail spikes featured a simple shape with a tapered end for easy insertion. Their design was effective but often required frequent maintenance and replacement.

4.2 Modern Spike Designs

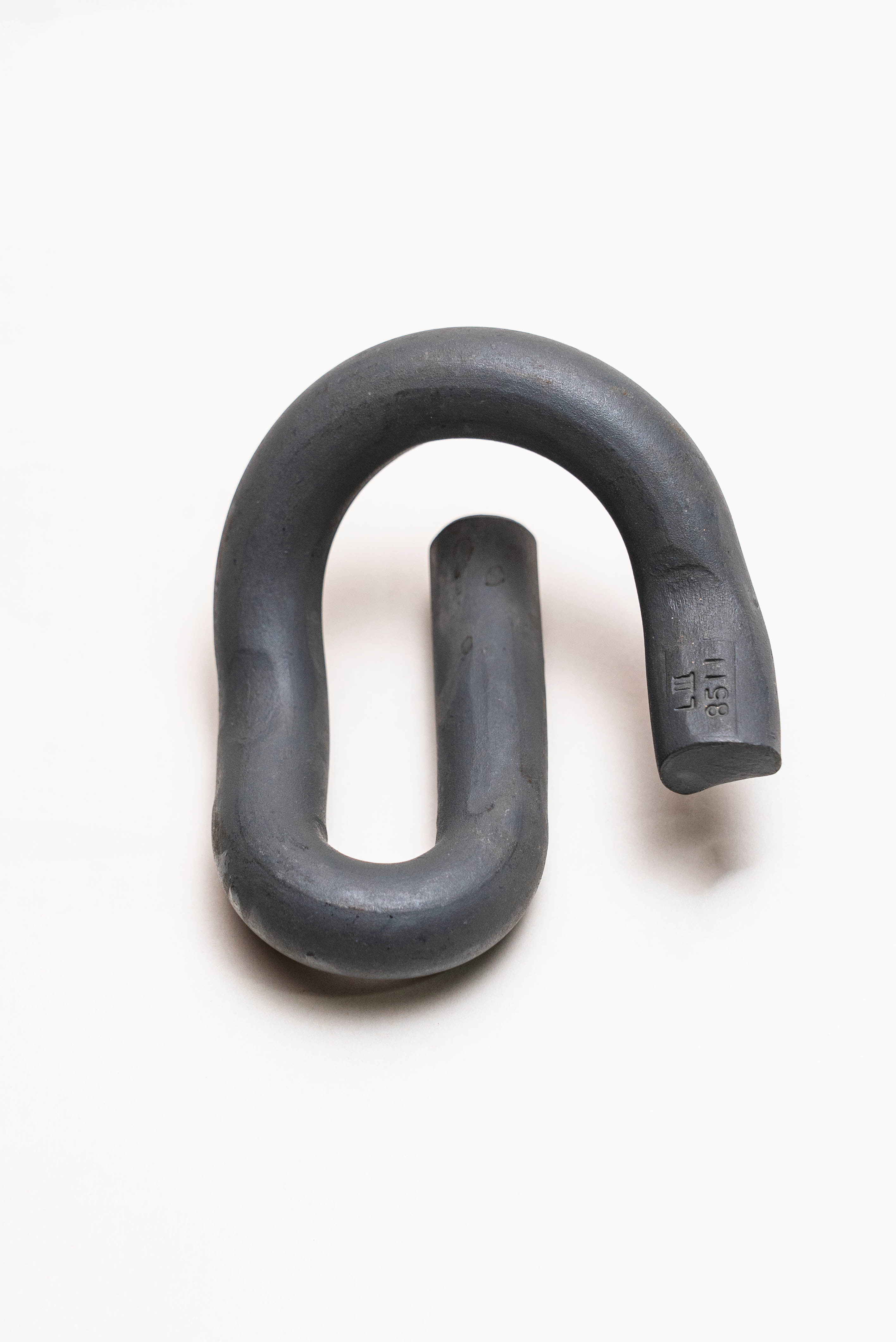

Modern spikes are engineered for optimal performance. Innovations include features such as broader heads for better load distribution, and designs that minimize the risk of loosening over time. For instance, the introduction of screw spikes and elastic fasteners has vastly improved the reliability of rail fastening systems.

5. The Role of Rail Track Spikes in Transportation Safety

Safety in rail transport hinges on the proper functioning of rail track spikes. These fasteners ensure that tracks remain securely aligned, preventing accidents caused by misaligned rails.

Regular inspections and maintenance of spikes are crucial in identifying wear and tear. Moreover, advancements in monitoring technology allow rail operators to assess the condition of spikes and make proactive adjustments, enhancing overall safety.

6. Manufacturing Processes: How Rail Track Spikes are Made

The manufacturing of rail track spikes involves several key processes to ensure their strength and durability.

6.1 Forging

The forging process shapes the spikes through the application of high pressure and temperature, aligning the grain structure of the metal for increased strength.

6.2 Heat Treatment

Heat treatment processes, such as quenching and tempering, are applied to steel spikes to enhance their toughness and resistance to wear.

6.3 Quality Control

Rigorous quality control measures are implemented at every stage of production to guarantee that each spike meets the stringent safety and performance standards required for rail applications.

7. The Future of Rail Track Spikes: Innovations and Trends

As the railway industry continues to evolve, so too do the technologies and materials used in rail track spikes.

Innovations such as smart spikes equipped with sensors could revolutionize monitoring and maintenance, providing real-time data on stress and integrity. Additionally, advancements in material science may lead to the development of lighter and more resilient spikes, further improving safety and reducing overall costs for railway operators.

8. Frequently Asked Questions

8.1 What are rail track spikes used for?

Rail track spikes secure rails to ties, providing stability and alignment essential for train safety.

8.2 How often should rail track spikes be inspected?

Regular inspections should be conducted at least twice a year, or more frequently in high-traffic areas.

8.3 What materials are rail track spikes made of?

Common materials include high-carbon steel, stainless steel, and, in some cases, composite materials.

8.4 Can rail track spikes be reused?

While some spikes can be reused if they are in good condition, it is generally recommended to replace worn or damaged spikes.

8.5 What advancements are being made in rail track spike technology?

Current advancements include the development of smart spikes with monitoring capabilities and the use of advanced materials to enhance durability.

9. Conclusion

The evolution of rail track spikes reflects the broader advancements in railway technology and safety practices. From their humble beginnings in wrought iron to the sophisticated, engineered designs of today, these fasteners are vital components in ensuring the safety and reliability of our rail systems. As we look to the future, continued innovations promise to enhance the performance and longevity of rail track spikes, underscoring their importance in the transportation infrastructure.

Previous:

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us