Why Quality Rail Track Spikes Are Essential for Safety

May 20,2025

Why Quality Rail Track Spikes Are Essential for Safety Table of Contents 1. Introduction to Rail Track Spikes 2. The Role of Rail Track Spikes in Rail Infrastructure 3. Types of Rail Track Spikes and Their Applications 3.1. Cut Spikes 3.2. Dog Spikes 3.3. Screw Spikes 4. Why Quality Matters in Rail Track Spikes 4.1. Material Composition 4.2. Manufacturing Standards 5. Safety

Why Quality Rail Track Spikes Are Essential for Safety

Table of Contents

1. Introduction to Rail Track Spikes

2. The Role of Rail Track Spikes in Rail Infrastructure

3. Types of Rail Track Spikes and Their Applications

3.1. Cut Spikes

3.2. Dog Spikes

3.3. Screw Spikes

4. Why Quality Matters in Rail Track Spikes

4.1. Material Composition

4.2. Manufacturing Standards

5. Safety Standards and Regulations

6. Benefits of Using High-Quality Rail Track Spikes

6.1. Enhanced Safety for Passengers and Cargo

6.2. Increased Longevity and Durability

7. Common Issues with Poor Quality Rail Track Spikes

7.1. Structural Failures

7.2. Increased Maintenance Costs

8. Conclusion

9. Frequently Asked Questions (FAQs)

1. Introduction to Rail Track Spikes

Rail track spikes are essential fasteners used to secure railroad ties to the rails, ensuring a stable and safe railway system. These seemingly small components play a significant role in the overall safety and reliability of train operations. When it comes to maintaining the integrity of rail infrastructure, the quality of rail track spikes cannot be overlooked.

2. The Role of Rail Track Spikes in Rail Infrastructure

Securing the rails to the wooden or concrete ties, rail track spikes help maintain correct gauge and alignment, which are crucial for the smooth and safe operation of trains. The function of these spikes is to absorb vibrations and shocks that occur as trains travel along the tracks. Proper fastening ensures that the tracks remain firmly in place, preventing derailments and accidents that could have dire consequences.

3. Types of Rail Track Spikes and Their Applications

Understanding the different types of rail track spikes available is vital for selecting the appropriate spike for specific applications.

3.1. Cut Spikes

Cut spikes are the traditional type of fastening, made from steel and featuring a tapered end. They are hammered directly into the tie, providing a strong hold. Cut spikes are often used in heavy-load rail systems due to their strength and reliability.

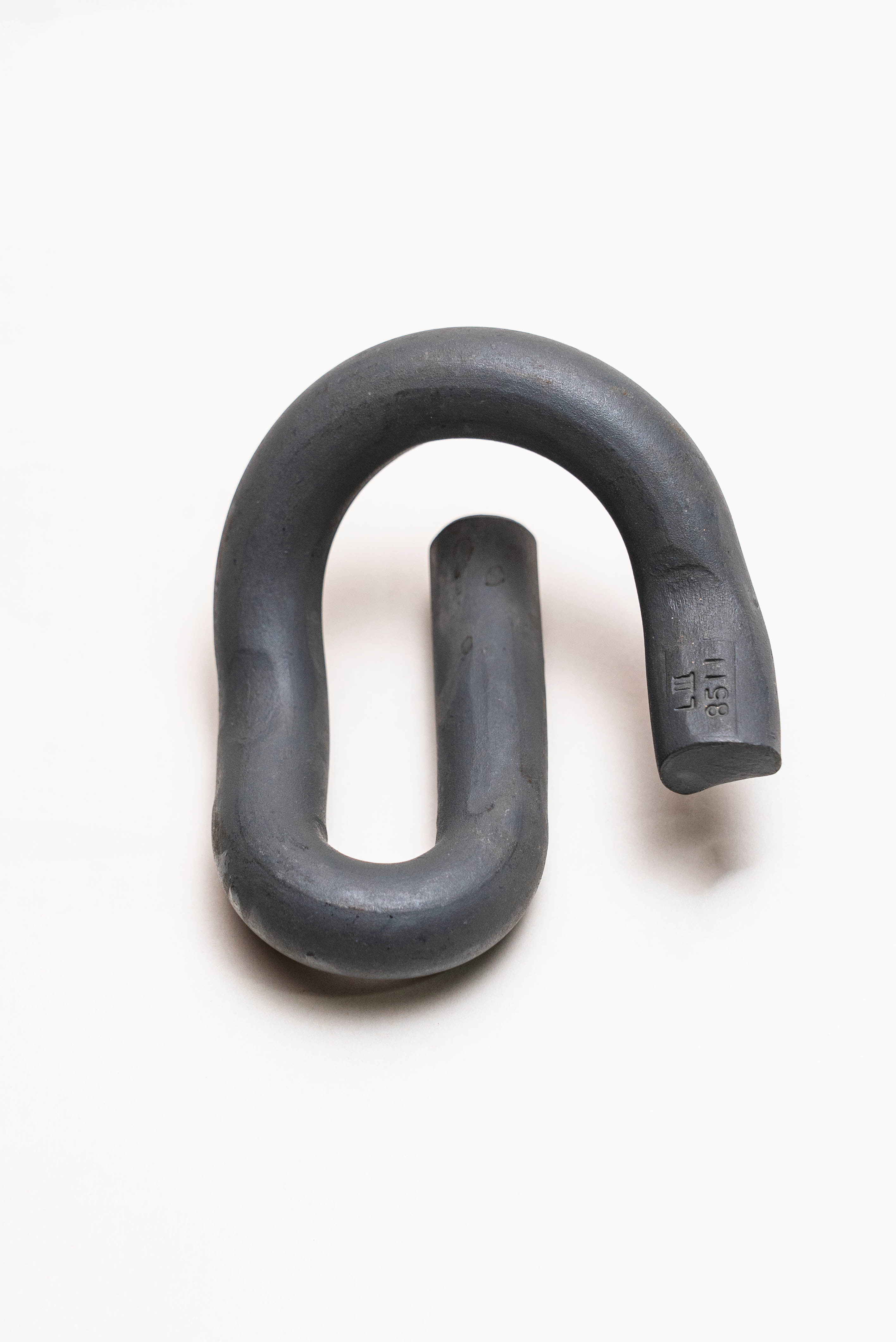

3.2. Dog Spikes

Dog spikes are designed with a curved, hook-like shape that goes over the rail base, providing a secure grip. These spikes are typically used in applications where removable rail installations are needed, offering flexibility in rail operations.

3.3. Screw Spikes

Screw spikes, characterized by their threaded design, offer superior holding power. They are screwed into the tie, reducing the risk of loosening over time. Their use is becoming increasingly popular in modern rail systems due to their enhanced security and ease of installation.

4. Why Quality Matters in Rail Track Spikes

The selection of high-quality rail track spikes is paramount for several reasons.

4.1. Material Composition

Quality rail track spikes are typically made from high-grade steel that can withstand significant stress and strain. The right material ensures that the spikes resist corrosion, wear, and breakage under heavy loads and harsh environmental conditions.

4.2. Manufacturing Standards

Adherence to stringent manufacturing standards is critical. Quality spikes undergo rigorous testing and quality control to ensure they meet industry safety requirements. Investing in spikes that comply with established standards can significantly reduce the risk of failures.

5. Safety Standards and Regulations

Railway safety is governed by strict national and international standards. Regulatory bodies mandate specific guidelines regarding the materials and designs of rail track spikes. Compliance with these regulations not only protects the integrity of the rail system but also the safety of passengers and freight.

6. Benefits of Using High-Quality Rail Track Spikes

Investing in quality rail track spikes brings numerous advantages that extend beyond safety.

6.1. Enhanced Safety for Passengers and Cargo

Quality spikes securely fasten the rails, reducing the risk of derailments that can result in catastrophic accidents. A well-maintained rail system safeguards both passengers and the freight being transported, building trust in the railway's reliability.

6.2. Increased Longevity and Durability

High-quality spikes are designed to endure the rigors of heavy loads and extreme weather conditions. Their durability translates to longer service life, reducing the frequency of replacements and maintenance.

7. Common Issues with Poor Quality Rail Track Spikes

Using subpar rail track spikes can lead to significant safety hazards and increased operational costs.

7.1. Structural Failures

Inadequate fastening can lead to track misalignment and structural failures, resulting in derailments. Such failures not only pose a danger to lives but can also cause severe disruptions to rail service.

7.2. Increased Maintenance Costs

Frequent replacements and repairs due to the use of low-quality spikes can inflate maintenance costs significantly. Investing in quality components up front can result in substantial savings over time.

8. Conclusion

In summary, the importance of quality rail track spikes cannot be overstated. They play an integral role in maintaining the safety and reliability of rail systems. By investing in high-quality spikes, railway operators can enhance safety, reduce maintenance costs, and ensure the longevity of their rail infrastructure. As we move forward, prioritizing quality will be essential in fostering a safer and more efficient transportation network.

9. Frequently Asked Questions (FAQs)

1. What materials are best for rail track spikes?

High-grade steel is preferred for its strength and resistance to wear and corrosion.

2. How do I know if my rail track spikes are of good quality?

Inspect for proper manufacturing standards, material quality, and compliance with safety regulations.

3. What are the consequences of using low-quality rail track spikes?

Using low-quality spikes can lead to derailments, increased maintenance costs, and operational disruptions.

4. How often should rail track spikes be inspected?

Regular inspections should be conducted as part of routine maintenance, ideally every six months, or more frequently in high-traffic areas.

5. Can I replace rail track spikes myself?

While it's possible to replace spikes with the right tools and knowledge, it is advisable to consult or hire professionals to ensure safety and compliance.

Previous:

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us