How Rail Fastening Systems Contribute to Sustainable Transportation Solutions

Jun 03,2025

How Rail Fastening Systems Contribute to Sustainable Transportation Solutions Table of Contents 1. Introduction to Rail Fastening Systems 2. Importance of Sustainable Transportation 3. Overview of Rail Fastening Systems 4. Benefits of Rail Fastening Systems in Sustainability 4.1 Efficiency in Energy Use 4.2 Enhanced Safety Measures 4.3

How Rail Fastening Systems Contribute to Sustainable Transportation Solutions

Table of Contents

- 1. Introduction to Rail Fastening Systems

- 2. Importance of Sustainable Transportation

- 3. Overview of Rail Fastening Systems

- 4. Benefits of Rail Fastening Systems in Sustainability

- 5. Environmental Impact of Rail Fastening Systems

- 6. Case Studies of Successful Implementations

- 7. Future Trends in Rail Fastening and Sustainability

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Rail Fastening Systems

Rail fastening systems are integral components of railway infrastructure, ensuring the secure attachment of rails to the underlying track structure. These systems play a crucial role in the overall performance and safety of rail networks, which are vital for sustainable transportation. By enhancing the stability and durability of rail systems, rail fastening contributes effectively to reducing maintenance costs and improving energy efficiency.

2. Importance of Sustainable Transportation

Sustainable transportation is essential in the context of global environmental challenges. The transition to greener modes of transport can significantly reduce carbon emissions, decrease dependency on fossil fuels, and minimize urban congestion. Rail systems, especially, stand out as one of the most efficient and environmentally friendly means of transportation. The integration of robust rail fastening systems directly impacts the sustainability of these transit solutions.

3. Overview of Rail Fastening Systems

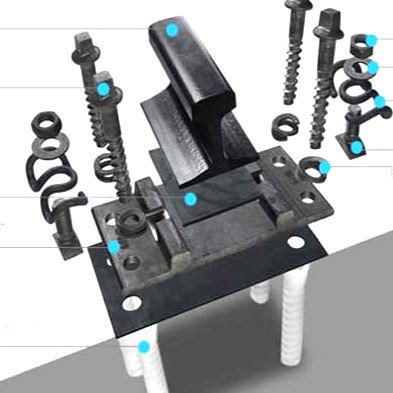

Rail fastening systems consist of various components, such as clips, pads, and anchors, designed to hold the rails firmly in place. These systems are engineered to withstand various forces, including dynamic loads from passing trains and environmental factors like temperature variations. The advanced materials and designs used in these systems contribute to their effectiveness and longevity, making them vital for maintaining the integrity of rail networks.

4. Benefits of Rail Fastening Systems in Sustainability

4.1 Efficiency in Energy Use

One of the primary benefits of rail fastening systems is their ability to enhance energy efficiency. By providing a stable track structure, these systems minimize track deformation and wear. This stability allows trains to operate at optimal speeds with lower energy consumption. The use of advanced fastening systems can lead to significant reductions in energy costs and greenhouse gas emissions, aligning with the goals of sustainable transportation.

4.2 Enhanced Safety Measures

Safety is paramount in transportation, and rail fastening systems contribute to this in several ways. A well-designed fastening system ensures that the rails remain securely in place, drastically reducing the risk of derailments. Furthermore, modern fastening systems often incorporate safety features such as vibration dampening, which not only protects the infrastructure but also enhances the comfort of passengers.

4.3 Cost-Effectiveness and Longevity

Investing in high-quality rail fastening systems can lead to significant long-term savings. Durable fastening systems reduce the need for frequent replacements and repairs, leading to lower maintenance costs. Their longevity also plays a vital role in minimizing disruptions to rail services, thus promoting more reliable and efficient transportation solutions.

5. Environmental Impact of Rail Fastening Systems

The environmental implications of rail fastening systems extend beyond immediate performance benefits. Their design and materials can significantly influence the overall sustainability of rail infrastructure.

5.1 Noise Reduction Technologies

Noise pollution is a significant concern in urban areas, especially with the expansion of rail networks. Innovative rail fastening systems are designed to mitigate noise through advanced materials and designs that absorb vibrations. By reducing noise levels, these systems not only improve the quality of life for nearby residents but also enhance the overall perception of rail transport as a sustainable alternative.

5.2 Recyclability of Materials

With growing emphasis on circular economy principles, the recyclability of rail fastening system materials is crucial. Many modern systems are constructed from recyclable materials, allowing for the reuse of components at the end of their lifecycle. This approach not only reduces waste but also minimizes the environmental impact associated with the production of new materials.

6. Case Studies of Successful Implementations

Examining real-world applications of rail fastening systems provides insights into their benefits and effectiveness in promoting sustainable transportation.

**Example 1: The Germany Rail Network**

Germany’s rail network has seen significant advancements in fastening technology, improving safety and reducing maintenance costs. The introduction of composite materials in fastening systems has led to increased durability and a reduction in noise pollution, contributing to a more sustainable transit solution.

**Example 2: High-Speed Rail in Japan**

Japan’s Shinkansen, or bullet train, exemplifies the successful implementation of rail fastening systems. The innovative technology used in their fastening mechanisms allows trains to operate at high speeds with remarkable stability, safety, and efficiency. This system has not only enhanced the performance of the rail network but also contributed to the overall environmental goals of the country.

7. Future Trends in Rail Fastening and Sustainability

As technology continues to evolve, so too will the rail fastening systems that support sustainable transportation. The future may see the integration of smart technologies, such as sensors that monitor system performance in real-time. This advancement could lead to predictive maintenance, where potential issues are addressed before they escalate, further enhancing sustainability.

Additionally, the use of advanced materials, including bio-based and recycled components, may dominate the market, reflecting a shift towards more environmentally friendly manufacturing practices. This evolution will not only improve the performance of rail fastening systems but also align with global sustainability efforts.

8. Conclusion

Rail fastening systems play a pivotal role in the quest for sustainable transportation solutions. Their contribution to energy efficiency, safety, cost-effectiveness, and environmental impact highlights their importance in modern rail infrastructure. As stakeholders in the transport sector continue to prioritize sustainable practices, investing in advanced rail fastening technologies will be essential. By recognizing the value of these systems, we can pave the way for a greener, more efficient future in transportation.

9. Frequently Asked Questions

**Q1: What are rail fastening systems?**

Rail fastening systems are components that secure the rails to the track structure, ensuring stability and safety during train operations.

**Q2: How do rail fastening systems contribute to energy efficiency?**

By providing a stable track structure, rail fastening systems minimize track deformation, allowing trains to operate at optimal speeds with reduced energy consumption.

**Q3: What materials are used in rail fastening systems?**

Rail fastening systems are typically made from a combination of steel, rubber, and composite materials, depending on the design and application requirements.

**Q4: How do these systems enhance safety in rail transport?**

Well-designed rail fastening systems reduce the risk of derailments by keeping rails securely in place, thus promoting safer rail operations.

**Q5: What is the environmental impact of rail fastening systems?**

Rail fastening systems can significantly reduce noise pollution and are often made from recyclable materials, contributing to a more sustainable transportation infrastructure.

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us