The Role of Rail Fastening Systems in Accelerating Urban Rail Projects

May 12,2025

The Role of Rail Fastening Systems in Accelerating Urban Rail Projects Urban rail projects are increasingly vital for modern cities, addressing the challenges of congestion, pollution, and the need for efficient public transport systems. At the heart of these projects is the critical technology of rail fastening systems. These systems play a pivotal role in ensuring the efficiency, safety, and lon

The Role of Rail Fastening Systems in Accelerating Urban Rail Projects

Urban rail projects are increasingly vital for modern cities, addressing the challenges of congestion, pollution, and the need for efficient public transport systems. At the heart of these projects is the critical technology of rail fastening systems. These systems play a pivotal role in ensuring the efficiency, safety, and longevity of rail networks. This article explores the significance of rail fastening systems in urban rail projects, elucidating their functions, benefits, and future prospects.

Table of Contents

1. Understanding Rail Fastening Systems

1.1 What are Rail Fastening Systems?

1.2 Components of Rail Fastening Systems

2. Importance of Rail Fastening Systems in Urban Rail Projects

2.1 Enhancing Safety and Stability

2.2 Improving Ride Quality and Comfort

3. Benefits of Advanced Rail Fastening Technologies

3.1 Accelerating Construction Timelines

3.2 Reducing Maintenance Costs

3.3 Environmental Impact and Sustainability

4. Innovations in Rail Fastening Systems

4.1 Development of New Materials

4.2 Smart Technologies and IoT Integration

5. Case Studies: Successful Urban Rail Projects

5.1 Global Examples of Effective Rail Fastening Implementation

6. Challenges and Solutions in Rail Fastening Systems

6.1 Addressing Installation Difficulties

6.2 Overcoming Environmental Factors

7. Future Trends in Rail Fastening Systems

7.1 Predictions for the Next Decade

8. FAQs

8.1 What are the different types of rail fastening systems?

8.2 How do rail fastening systems contribute to noise reduction?

8.3 What materials are commonly used in rail fastening systems?

8.4 How often do rail fastening systems require maintenance?

8.5 What role do rail fastening systems play in high-speed rail projects?

9. Conclusion

1. Understanding Rail Fastening Systems

1.1 What are Rail Fastening Systems?

Rail fastening systems are specialized components that secure the rails to the underlying track structure, typically concrete or wooden sleepers. These systems are designed to maintain the alignment and stability of the tracks, ensuring that trains run smoothly and safely.

1.2 Components of Rail Fastening Systems

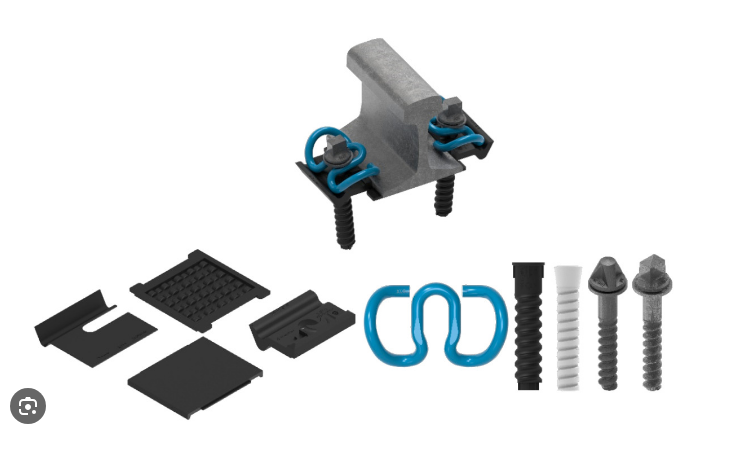

A typical rail fastening system consists of several key components, including clips, bolts, and pads. The clips hold the rail in place, while the bolts provide additional security. Pads, often made from rubber or other flexible materials, help absorb vibrations, enhancing the overall ride quality.

2. Importance of Rail Fastening Systems in Urban Rail Projects

2.1 Enhancing Safety and Stability

Safety is paramount in urban rail systems. Rail fastening systems contribute to the overall stability of the rail tracks, preventing misalignment and potential derailments. This stability is especially crucial in densely populated urban areas where safety concerns are heightened.

2.2 Improving Ride Quality and Comfort

The comfort of passengers is an essential consideration in urban rail projects. Advanced rail fastening systems help mitigate vibrations and noise, resulting in a smoother and more enjoyable journey for commuters. This enhancement is vital for encouraging the use of public transport over personal vehicles.

3. Benefits of Advanced Rail Fastening Technologies

3.1 Accelerating Construction Timelines

One of the most significant advantages of modern rail fastening systems is their ease of installation. Advanced fastening technologies allow for quicker assembly and disassembly, dramatically reducing construction timelines. This efficiency is particularly beneficial in urban environments where project delays can lead to increased costs and public dissatisfaction.

3.2 Reducing Maintenance Costs

With the introduction of durable materials and innovative designs, modern rail fastening systems require less frequent maintenance. This reduction in upkeep not only cuts costs but also minimizes service disruptions, ensuring that urban rail services operate smoothly.

3.3 Environmental Impact and Sustainability

The environmental impact of rail systems is an important consideration. Rail fastening systems that utilize sustainable materials and practices contribute to the overall ecological footprint of urban rail projects. This focus on sustainability resonates with environmentally-conscious urban planners and city residents alike.

4. Innovations in Rail Fastening Systems

4.1 Development of New Materials

Recent advancements in materials science have led to the development of new, lightweight, and strong materials for rail fastening systems. These materials not only enhance performance but also improve the durability and lifespan of the fastening systems.

4.2 Smart Technologies and IoT Integration

The integration of smart technologies and the Internet of Things (IoT) into rail fastening systems is revolutionizing urban rail projects. Sensors embedded in fastening components can monitor performance in real-time, allowing for predictive maintenance and immediate responses to potential issues.

5. Case Studies: Successful Urban Rail Projects

5.1 Global Examples of Effective Rail Fastening Implementation

Cities around the world are successfully implementing advanced rail fastening systems in their urban rail projects. For instance, the implementation of resilient fastening systems in the London Crossrail project has significantly improved track stability and reduced noise pollution. Similarly, the use of innovative fastening technologies in the Sydney Light Rail has accelerated project timelines while enhancing passenger comfort.

6. Challenges and Solutions in Rail Fastening Systems

6.1 Addressing Installation Difficulties

Despite the advantages, the installation of rail fastening systems can pose challenges, particularly in urban settings with limited space. Solutions such as modular systems and prefabricated components can streamline the installation process, ensuring a more efficient workflow.

6.2 Overcoming Environmental Factors

Environmental factors such as extreme weather can impact the performance of rail fastening systems. Research and development efforts are focusing on creating systems that can withstand various climatic conditions, ensuring reliability and safety year-round.

7. Future Trends in Rail Fastening Systems

7.1 Predictions for the Next Decade

Looking ahead, the future of rail fastening systems is bright, with trends pointing towards greater automation, smart technologies, and increased sustainability. As urban areas continue to expand and the demand for efficient public transport grows, rail fastening systems will evolve to meet these challenges, ensuring the continued success of urban rail projects.

8. FAQs

8.1 What are the different types of rail fastening systems?

There are several types of rail fastening systems, including screw spike systems, clip systems, and elastic rail fastening systems. Each type is designed for specific applications and conditions.

8.2 How do rail fastening systems contribute to noise reduction?

Rail fastening systems designed with rubber pads or similar materials can absorb vibrations, thereby reducing noise levels generated by passing trains. This is particularly important in urban areas where noise pollution is a concern.

8.3 What materials are commonly used in rail fastening systems?

Common materials include steel for strength, rubber for vibration absorption, and composite materials for lightweight applications. The choice of material often depends on environmental conditions and performance requirements.

8.4 How often do rail fastening systems require maintenance?

The maintenance frequency of rail fastening systems depends on various factors, including usage, environmental conditions, and the materials used. However, modern systems often require less frequent maintenance due to their advanced design and materials.

8.5 What role do rail fastening systems play in high-speed rail projects?

In high-speed rail projects, rail fastening systems are crucial for maintaining track stability at high speeds. Their design must accommodate dynamic forces and provide exceptional alignment and damping capabilities.

9. Conclusion

Rail fastening systems are fundamental to the success of urban rail projects. Their ability to enhance safety, improve ride quality, and reduce maintenance costs makes them indispensable in the modern transportation landscape. As technology continues to advance, these systems will play an even greater role in shaping efficient and sustainable urban transit solutions. The future of urban rail is bright, and rail fastening systems will undoubtedly be at the forefront of this transformation.

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us