-

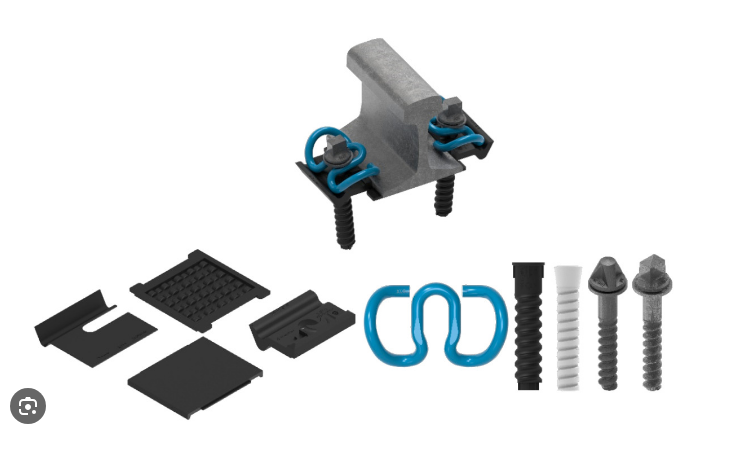

ProductsAt present, the company has the ability to produce 50000 tons of rail buckle accessories annually. The product series includes various specifications of spring bars Gauge baffles, switch special pads, joint clamps for 43kg, 50kg, 60kg steel rails, various export products, etc

-

-

AboutThe company was established in 1994 and is a production enterprise specializing in the research and development, production, and sales of railway line specific accessories

The Role of Rail Elastomers in Modern Rail Transportation

May 21,2025

Rail elastomers are specialized materials used in the railway industry that play an essential role in enhancing the performance and safety of rail systems. These materials are typically rubber-like substances designed to absorb vibrations, reduce noise, and provide cushioning in various components of rail transport systems. Their unique properties make them a vital part of rail vehicle design, mai

One of the primary functions of rail elastomers is vibration dampening. As trains travel at high speeds, they generate significant vibrations, which can lead to discomfort for passengers and potential structural damage over time. Rail elastomers help mitigate these vibrations by absorbing them, thus ensuring a smoother ride and prolonging the lifespan of railway infrastructure. By reducing the intensity of vibrations that reach the train and its components, rail elastomers contribute to better overall system performance.

In addition to vibration dampening, rail elastomers also play a critical role in noise reduction. The sound generated by moving trains can be disruptive, especially in urban areas where rail lines run close to residential neighborhoods. By incorporating rail elastomers in various parts of the train, such as undercarriage components and track systems, noise levels can be significantly reduced. This not only improves passenger comfort but also helps maintain good relationships with communities located near rail lines.

Another important application of rail elastomers is in the design of track and wheel interfaces. These materials provide a flexible connection between the train wheels and the tracks, allowing for better adaptability to track irregularities. This flexibility is essential in maintaining stability and safety, particularly on curves and transitions. The use of rail elastomers in this context ensures that trains can operate efficiently while minimizing wear and tear on both the wheels and the tracks.

Furthermore, rail elastomers are resistant to environmental factors such as temperature fluctuations, UV radiation, and moisture. This durability makes them suitable for various climatic conditions encountered in the railway industry. Whether exposed to the heat of summer or the cold of winter, rail elastomers retain their performance characteristics, ensuring consistent operation throughout the year.

In conclusion, rail elastomers are indispensable in the realm of rail transportation. Their ability to absorb vibrations, reduce noise, and enhance the flexibility of track systems makes them a fundamental component in modern rail vehicle design. As the rail industry continues to evolve with a focus on improving passenger experience and operational efficiency, the importance of rail elastomers is set to grow, paving the way for safer, quieter, and more reliable rail systems.

Next:

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us

Henan Xinda Railway Equipment Co., Ltd

Fax: +86-372-2615999

Tel: +86-18567891234

Email:info@xindarail.com

Send us your request

we will get in touch with you as soon as possible

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.