Future-Proofing Rail Systems: The Role of Advanced Elastomers

May 22,2025

Future-Proofing Rail Systems: The Role of Advanced Elastomers Table of Contents 1. Introduction to Advanced Elastomers in Rail Systems 2. Understanding Elastomers: What They Are and How They Work 3. The Importance of Advanced Elastomers in Rail Transportation 3.1 Improved Durability and Longevity 3.2 Enhanced Safety Features 4. Innovations in Elastomer Technology 4.1 Smart Elastomers for Predictiv

Future-Proofing Rail Systems: The Role of Advanced Elastomers

Table of Contents

1. Introduction to Advanced Elastomers in Rail Systems

2. Understanding Elastomers: What They Are and How They Work

3. The Importance of Advanced Elastomers in Rail Transportation

3.1 Improved Durability and Longevity

3.2 Enhanced Safety Features

4. Innovations in Elastomer Technology

4.1 Smart Elastomers for Predictive Maintenance

4.2 Eco-Friendly Elastomer Solutions

5. Applications of Advanced Elastomers in Rail Systems

5.1 Vibration Dampening and Noise Reduction

5.2 Sealing and Insulation Applications

6. Challenges and Considerations in Implementing Advanced Elastomers

6.1 Cost Implications

6.2 Material Compatibility and Sourcing

7. Future Trends in Rail Systems and Elastomer Usage

8. FAQs About Advanced Elastomers in Rail Systems

9. Conclusion

1. Introduction to Advanced Elastomers in Rail Systems

The **rail transportation industry** is undergoing a significant transformation, driven by the need for improved efficiency, safety, and sustainability. One of the most pivotal developments in this evolution is the integration of **advanced elastomers**. These innovative materials are not only enhancing the performance of rail systems but also setting a foundation for future advancements. In this article, we will delve into the critical role of advanced elastomers, exploring their benefits, applications, and the challenges faced in their implementation.

2. Understanding Elastomers: What They Are and How They Work

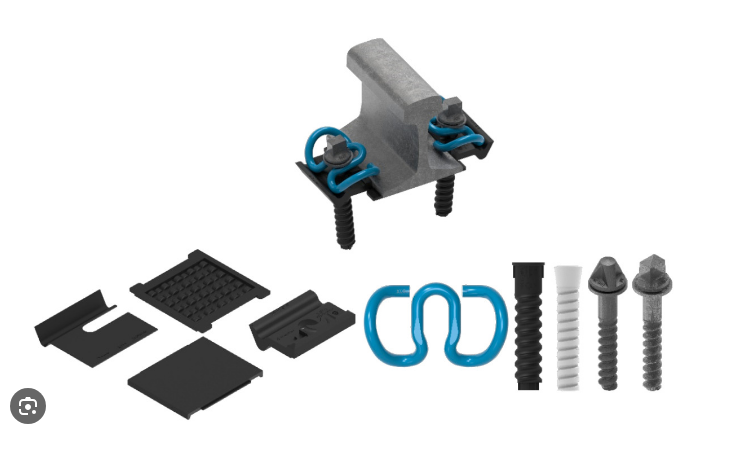

Elastomers are a class of polymers characterized by their elasticity and flexibility. These materials can undergo significant deformation under stress and return to their original shape when the stress is removed. Advanced elastomers, specifically engineered for performance, exhibit superior mechanical properties, chemical resistance, and durability. They are essential in various components of rail systems, including seals, gaskets, and vibration dampers.

3. The Importance of Advanced Elastomers in Rail Transportation

As rail systems worldwide strive to meet increasing demands for efficiency and safety, the role of advanced elastomers has become even more pronounced. Their unique properties contribute to several critical aspects of rail transportation.

3.1 Improved Durability and Longevity

Advanced elastomers boast remarkable resistance to wear and tear, significantly extending the lifespan of components in rail systems. This durability translates into reduced maintenance costs and less frequent replacements, ultimately enhancing operational efficiency.

3.2 Enhanced Safety Features

Safety is paramount in rail transportation. Advanced elastomers contribute to safety in various ways, such as providing effective sealing solutions that prevent leaks and failures. Additionally, their excellent vibration dampening properties minimize the risk of structural damage and enhance passenger comfort.

4. Innovations in Elastomer Technology

The ongoing research and development in elastomer technology are yielding innovative solutions that are reshaping rail systems.

4.1 Smart Elastomers for Predictive Maintenance

Emerging technologies are enabling the creation of **smart elastomers** that can monitor their condition and performance in real time. These materials can alert maintenance teams to potential issues before they escalate into significant problems, thus enhancing safety and reliability.

4.2 Eco-Friendly Elastomer Solutions

Sustainability is a crucial concern in modern transportation. Advanced elastomers are being developed with eco-friendly materials and processes, reducing environmental impact while maintaining high performance levels. This shift aligns with global initiatives toward greener transportation solutions.

5. Applications of Advanced Elastomers in Rail Systems

The versatility of advanced elastomers allows for their application across various functions within rail systems.

5.1 Vibration Dampening and Noise Reduction

Rail networks often face challenges related to vibrations and noise. Advanced elastomers are used in vibration dampers and sound insulation materials, significantly reducing noise pollution and improving ride quality.

5.2 Sealing and Insulation Applications

Effective sealing is critical in rail systems to prevent water ingress and ensure the safety of electrical components. Advanced elastomers provide reliable sealing solutions that withstand extreme environmental conditions, enhancing operational reliability.

6. Challenges and Considerations in Implementing Advanced Elastomers

While the benefits of advanced elastomers are compelling, several challenges must be navigated during implementation.

6.1 Cost Implications

The initial investment in advanced elastomer technology can be substantial. Organizations must weigh the long-term benefits against the upfront costs, considering the potential for reduced maintenance and improved efficiency.

6.2 Material Compatibility and Sourcing

Not all elastomers are suitable for every application. Ensuring material compatibility with existing systems and sourcing high-quality materials can pose challenges for rail operators.

7. Future Trends in Rail Systems and Elastomer Usage

The future of rail transportation is closely tied to advancements in elastomer technology. As the industry moves toward more automated and efficient systems, the demand for specialized elastomers will likely increase. Innovations in **smart materials** and **sustainable practices** will play a significant role in shaping the next generation of rail systems.

8. FAQs About Advanced Elastomers in Rail Systems

What are advanced elastomers?

Advanced elastomers are high-performance materials designed to exhibit superior elasticity, durability, and resistance to environmental factors. They are used in various applications within rail systems to enhance performance and safety.

How do advanced elastomers improve rail safety?

These materials provide effective sealing solutions to prevent leaks, reduce vibration-related risks, and enhance overall ride quality, contributing to a safer rail environment.

Are advanced elastomers environmentally friendly?

Many advanced elastomers are developed with sustainability in mind, utilizing eco-friendly materials and processes to minimize environmental impact.

What applications do advanced elastomers have in rail systems?

They are used in vibration dampening, noise reduction, sealing, and insulation applications, enhancing the performance and safety of rail systems.

What challenges exist in implementing advanced elastomers?

Challenges include cost implications, material compatibility with existing systems, and sourcing high-quality materials. Organizations must navigate these issues to successfully integrate advanced elastomers.

9. Conclusion

Advanced elastomers are revolutionizing the rail transportation industry by providing enhanced durability, safety, and sustainability. As we look to the future, the continued development and implementation of these materials will play a crucial role in shaping efficient and reliable rail systems. Embracing advanced elastomers not only ensures the longevity of rail infrastructure but also aligns with global goals for greener transportation solutions. The journey toward future-proof rail systems is well underway, and advanced elastomers will be at the forefront of this evolution.

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us