-

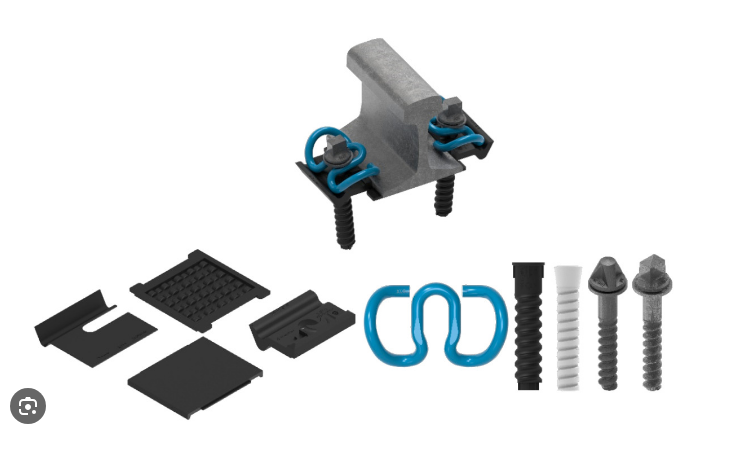

ProductsAt present, the company has the ability to produce 50000 tons of rail buckle accessories annually. The product series includes various specifications of spring bars Gauge baffles, switch special pads, joint clamps for 43kg, 50kg, 60kg steel rails, various export products, etc

-

-

AboutThe company was established in 1994 and is a production enterprise specializing in the research and development, production, and sales of railway line specific accessories

Understanding Rail Elastomer: The Backbone of Railway Vibration Management

May 23,2025

Rail elastomers represent a crucial component in the realm of rail transportation, particularly in the context of railway infrastructure. These materials are specifically designed to manage vibrations and mitigate noise generated by passing trains. By absorbing shocks and vibrations, rail elastomers contribute to a smoother ride for passengers while simultaneously protecting the structural integri

The primary function of rail elastomers lies in their ability to dampen vibrations that occur during train operations. When a train travels over tracks, it creates dynamic forces that can lead to significant wear and tear on the track structure. Rail elastomers are strategically placed between the rail and the sleeper (the horizontal support for the rails) to absorb these forces. This not only reduces the transmission of vibrations to surrounding environments but also decreases the potential for track deformation and damage over time.

One of the significant benefits of utilizing rail elastomers is the improvement in passenger comfort. By minimizing the vibrations and noise associated with train travel, these materials enhance the overall travel experience, which is especially critical in urban areas where noise pollution is a concern. Furthermore, rail elastomers play a vital role in extending the lifespan of railway components, thereby reducing maintenance costs and downtime.

In addition to their vibration-dampening capabilities, rail elastomers are designed to withstand various environmental conditions. They are typically made from high-performance synthetic rubber compounds, ensuring durability and resilience against factors such as temperature fluctuations, moisture, and UV exposure. This robustness is essential for maintaining operational efficiency in diverse climates, ensuring that rail systems remain reliable and safe for users.

Moreover, the installation of rail elastomers can also contribute to the sustainability of rail systems. By reducing noise pollution and enhancing ride quality, these materials help promote rail transport as a viable and eco-friendly alternative to road transport. With growing concerns about environmental impact and urban congestion, the role of rail elastomers in fostering sustainable transport solutions cannot be understated.

In conclusion, rail elastomers are indispensable in modern railway systems. Their ability to manage vibrations, enhance passenger comfort, and protect infrastructure aligns with the industry's goals of safety, sustainability, and efficiency. As the demand for reliable and efficient rail transport continues to rise, understanding the significance of rail elastomers becomes increasingly vital for professionals in the field.

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us

Henan Xinda Railway Equipment Co., Ltd

Fax: +86-372-2615999

Tel: +86-18567891234

Email:info@xindarail.com

Send us your request

we will get in touch with you as soon as possible

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.