The Best Practices for Installing Rail Elastomer Components: A Comprehensive Guide for Optimal Performance

May 24,2025

The Best Practices for Installing Rail Elastomer Components Table of Contents 1. Understanding Rail Elastomer Components 2. Importance of Rail Elastomer Components in Transportation 3. Pre-installation Considerations 4. Installation Techniques for Rail Elastomer Components 5. Quality Control Measures During Installation 6. Common Mistakes to Avoid When Installing Rail Elas

The Best Practices for Installing Rail Elastomer Components

Table of Contents

- 1. Understanding Rail Elastomer Components

- 2. Importance of Rail Elastomer Components in Transportation

- 3. Pre-installation Considerations

- 4. Installation Techniques for Rail Elastomer Components

- 5. Quality Control Measures During Installation

- 6. Common Mistakes to Avoid When Installing Rail Elastomer Components

- 7. Maintenance and Monitoring of Rail Elastomer Components

- 8. Future Trends in Rail Elastomer Technology

- 9. Frequently Asked Questions

1. Understanding Rail Elastomer Components

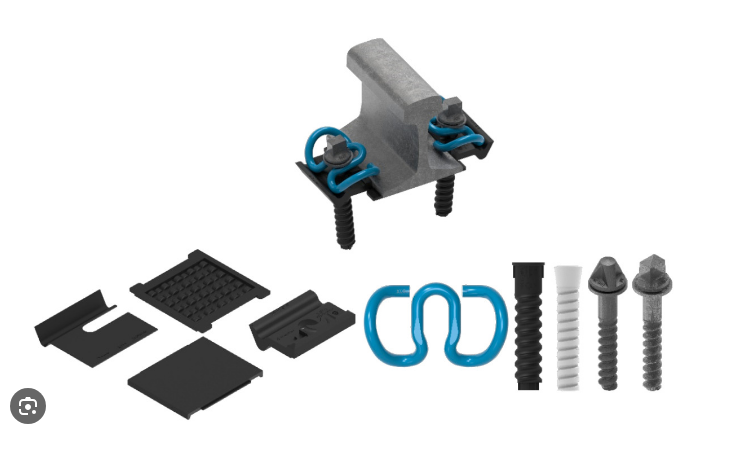

Rail elastomer components play a vital role in the functionality of modern railway systems. These components, made from high-performance elastomer materials, are designed to absorb vibrations, reduce noise, and provide stability to the rail infrastructure. Understanding their structure and purpose is the first step in ensuring optimal installation.

Elastomers are synthetic or natural polymers that exhibit elastic properties, making them ideal for applications where flexibility and durability are required. In rail systems, elastomer components include rail pads, dampers, and bushings, all of which contribute to the overall safety and performance of the rail network.

2. Importance of Rail Elastomer Components in Transportation

The integration of rail elastomer components into transportation systems is crucial for various reasons:

- **Vibration Damping**: These components minimize vibrations caused by moving trains, ensuring a smoother ride for passengers and reducing wear on the tracks.

- **Noise Reduction**: Rail elastomers effectively absorb sound, contributing to quieter train operations, which is vital for urban areas where noise pollution is a concern.

- **Increased Lifespan of Infrastructure**: By reducing the stress on tracks and other structural elements, elastomer components extend the lifespan of the railway infrastructure.

- **Safety Enhancements**: Properly installed elastomer components contribute to the safe operation of trains by maintaining track alignment and reducing derailment risks.

3. Pre-installation Considerations

Before installing rail elastomer components, several factors must be considered to ensure a successful installation.

3.1 Site Assessment

Conduct a thorough assessment of the installation site. Examine existing infrastructure conditions, including track alignment, subgrade conditions, and potential environmental impacts. Understanding these factors will help in selecting the right elastomer components for the job.

3.2 Material Selection

Choose high-quality elastomer materials that meet industry standards. Factors such as temperature resistance, chemical exposure, and mechanical properties of the elastomer should be evaluated. Collaborate with suppliers to identify the best fit for your specific application.

3.3 Installation Team Training

Ensure that installation teams are well-trained in the specific requirements for handling and installing rail elastomer components. Invest in training programs that cover best practices, safety protocols, and troubleshooting techniques.

4. Installation Techniques for Rail Elastomer Components

Implementing the right installation techniques is critical for the performance and durability of rail elastomer components.

4.1 Proper Alignment

Ensure that all elastomer components are properly aligned with the rail system before installation. Misalignment can lead to premature wear and failure.

4.2 Controlled Compression

Apply controlled compression during the installation process. Over-compression can damage elastomer components, while under-compression may lead to ineffective performance.

4.3 Securing Fasteners

Use the appropriate type and size of fasteners to secure elastomer components. Tighten fasteners to the manufacturer’s specifications to avoid issues related to loosening or excessive strain.

4.4 Environmental Considerations

Protect elastomer components from extreme weather conditions during installation. Avoid exposing them to direct sunlight or harsh chemicals before they are installed, as these can degrade their performance.

5. Quality Control Measures During Installation

Implementing quality control measures during installation is essential for maintaining high standards and ensuring the longevity of rail elastomer components.

5.1 Regular Inspections

Conduct regular inspections during the installation process to identify any potential issues early. This includes checking for proper alignment, compression levels, and securing methods.

5.2 Documentation

Maintain thorough documentation throughout the installation process. Recording material specifications, installation procedures, and any deviations from the plan will help in future maintenance and troubleshooting efforts.

5.3 Performance Testing

After installation, perform performance testing to ensure that the rail elastomer components are functioning as intended. This may involve measuring vibration levels, noise reduction capabilities, and overall structural integrity.

6. Common Mistakes to Avoid When Installing Rail Elastomer Components

Understanding common mistakes can prevent costly errors and enhance the effectiveness of the installation.

6.1 Ignoring Manufacturer Guidelines

Always adhere to the manufacturer’s installation guidelines. Neglecting these instructions can lead to improper installation and subsequent failures.

6.2 Skipping Pre-Installation Checks

Do not overlook pre-installation checks. Ensuring that the site is ready and that components are suitable for the environment can save time and resources.

6.3 Inadequate Training

Avoid assigning installation tasks to untrained personnel. Proper training is essential for ensuring a successful installation.

7. Maintenance and Monitoring of Rail Elastomer Components

Once installed, regular maintenance and monitoring are crucial for ensuring the continued performance of rail elastomer components.

7.1 Scheduled Inspections

Establish a routine inspection schedule to monitor the condition of elastomer components. Look for signs of wear, degradation, or misalignment.

7.2 Performance Evaluation

Evaluate the performance of rail elastomer components periodically. Assess vibration and noise levels to determine if any adjustments or replacements are necessary.

7.3 Timely Replacements

Replace worn or damaged elastomer components promptly to prevent further issues in the rail system. Timely intervention can protect the integrity of the entire rail infrastructure.

8. Future Trends in Rail Elastomer Technology

As technology advances, rail elastomer components continue to evolve. Below are some promising trends to watch for in the coming years:

8.1 Sustainable Materials

The use of sustainable and eco-friendly materials for elastomer components is likely to increase. This shift will contribute to environmental conservation efforts within the transport sector.

8.2 Smart Technologies

Integrating smart technologies into rail elastomer components may enhance monitoring and performance tracking. Sensors can provide real-time data on component conditions, facilitating proactive maintenance.

8.3 Enhanced Durability

Research and development focus on creating elastomer materials with improved durability and resistance to environmental factors. This will lead to longer-lasting components and reduced maintenance costs.

9. Frequently Asked Questions

9.1 What are rail elastomer components?

Rail elastomer components are specialized materials used in railway systems to reduce vibrations, noise, and provide stability. They include rail pads, dampers, and bushings.

9.2 Why are proper installation techniques important?

Proper installation techniques ensure that rail elastomer components perform effectively and last longer. Incorrect installation can lead to early failure and safety risks.

9.3 How often should rail elastomer components be inspected?

It is recommended to conduct inspections of rail elastomer components regularly, typically every six months to a year, depending on usage and environmental conditions.

9.4 What should I do if I notice wear on elastomer components?

If wear is detected, it is crucial to evaluate the extent of the damage. If significant, schedule a replacement to maintain the integrity of the rail system.

9.5 Are there advancements in rail elastomer technology?

Yes, advancements include the development of sustainable materials and smart technologies that enhance monitoring and performance tracking in rail elastomer components.

Conclusion

Installing rail elastomer components correctly is imperative for ensuring the safety, efficiency, and longevity of railway systems. By adhering to best practices in installation, maintenance, and monitoring, professionals can optimize the performance of these critical components. Embracing future trends will not only enhance current practices but also pave the way for innovations that contribute to safer and more sustainable rail transportation.

Recommended

There is one sheet production line and two high-precision engraving machines, with an annual production capacity of 6 million railway special height adjustment pads.

Electrostatic spraying workshop

There is one electrostatic spray equipment production line and one spray paint production line, with an annual production capacity of 10,000 tons.

Contact Us