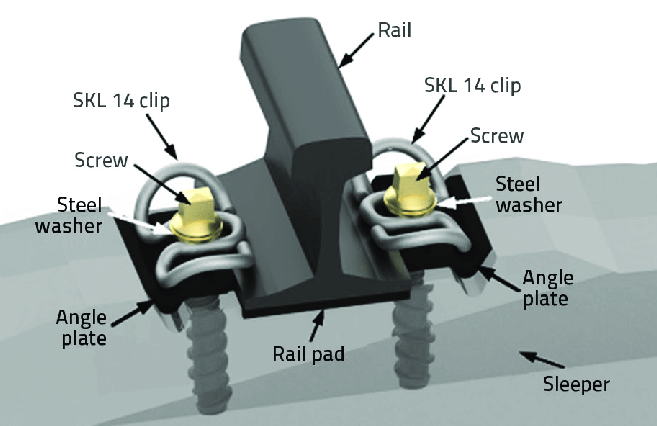

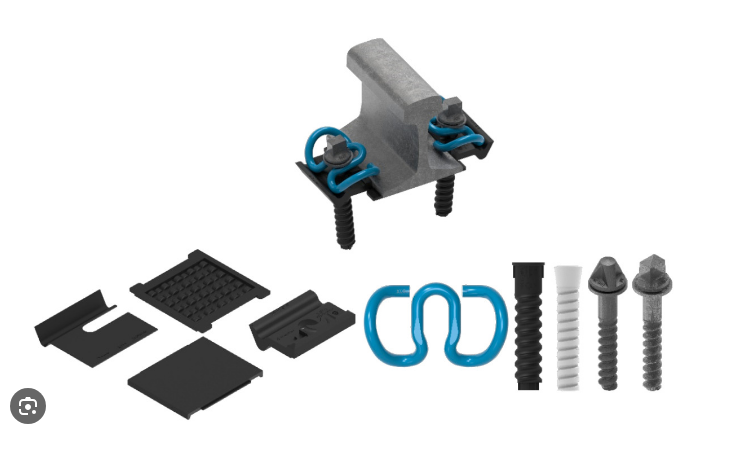

The rail fastening system W14 type is designed for railway lines representing the A, B, C and D category according to PN-EN 13481-2:2017 norm with a maximum permissible axle load of 260kN. Depending on the requirements of the client, the system is provided with a rail pad of high or low static stiffness. Due to the mid-loop of the clip, which is situated over the rail foot, the rail fastening is characterized by additional elasticity. This eliminates the possibility of overloading the clips’ arms and their plastic deformation as well as prevents the rotation of the rail. The system meets the requirements of norm PN-EN 13481-2:2017.

1. Gauge: 1435mm

2. Longitudinal resistance of steel rail: Generally, the section is larger than 9kN (each group of fasteners), and the section with low resistance is the section (each group of fasteners).

3. Node stiffness: the static stiffness of the pad under the rail is 25-40kN/mm, and the node static stiffness of the fastener system is 30±5kN/mm.

4. Fatigue performance: The fastener system is tested in accordance with EN13146-4. After 3 million load cycles, the parts are not damaged, the gauge expansion is less than 6mm, and the buckle force change is ≤20%, and the rail longitudinal resistance change is ≤20%. The change of the static stiffness of the node is less than or equal to 25%. (Test load parameter: Pv/cosα=56kN L/V=0.50, α=26°,α=26°).

5. Insulation resistance: The fastener system is tested in accordance with EN13146-5, and the insulation resistance between the two rails is greater than 3Ω·km, and meets the requirements of the track circuit.

6. The impact of harsh environmental conditions: After the fastener system has been subjected to the 300h salt spray test described in EN13146-6, it can be smoothly disassembled with a manual disassembly tool.

7. Rail left and right position adjustment: Single strand rail left and right position adjustment: -5~+5mm; Gauge adjustment: -10~+10mm,

The adjustment level is 1mm.

8. The adjustment amount of rail height: 20mm; the adjustment level is 1mm.

9. Spring bar buckle pressure and spring range: Type II spring bar: buckle pressure is greater than 5.5kN, and the spring range is 10mm.

10. Pull-out resistance of embedded casing: not less than 60kN.

The advantages of AL series fasteners compared with other urban rail transit fasteners:

1. The baseplate under the rail is made of high-strength, low-rigidity nylon instead of cast iron and rubber under the iron plate. The manufacturing process is relatively environmentally friendly, with fewer parts, and nylon has good durability, unlike the iron backing plate that has corrosion.

2. The insulation performance of the under-rail substrate made of nylon is far greater than that of other fasteners, which protects the under-rail foundation from stray currents.

3. Adopt general II type elastic clips as fastening parts, adopt general spikes, casings, and gauge blocks, which are convenient for installation and maintenance.

And has versatility and interchangeability.

4. The structure is simple and light, which reduces the labor intensity of workers during paving construction and maintenance.

5. The rigidity of the base plate under the rail is much smaller than that of the iron plate, which can reduce vibration and noise.

The Essential Role of the Rail Fastening System in Railway Infrastructure

A rail fastening system is a crucial component in the world of railway infrastructure. It serves as the connection between the rail and the underlying support structure, ensuring the safe and efficient operation of trains.

The rail fastening system is designed with precision and engineering excellence. It typically consists of various elements such as clips, fasteners, and insulators. These components work in harmony to hold the rail firmly in place. The clips, for instance, are carefully shaped to grip the rail with the right amount of force. They are made from high - quality materials, often steel alloys, which provide strength and durability. This is essential as they need to withstand the constant vibrations and heavy loads exerted by passing trains.

W-14 Rail Fastening System

Contact

Classification

Product Inquiry

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible

Related Products

Advanced E1809 rail clip for secure rail-to-sleeper fastening. Spring steel construction with anti-corrosion coating. Ideal for metros, light rail & industrial lines. UIC/ISO certified.

High-Performance Rail Clips for Secure & Durable Railway Track Fastening Systems

ISO-Certified Rail Clips ✓ Spring Steel Construction ✓ Corrosion Resistance ✓ 25+ Year Lifespan. Ensure Track Stability & Safety. Download Technical Specs!

Rail Clamps: The Unsung Heroes of Railway Safety & Stability Xinda can produce railway clamps in accordance with DIN, GB/TB, regional standards and customer drawings. For example, according to AREMA, the range is 52 lb rail, 62 lb rail, 114 lb rail, 106 lb rail, 120 lb rail, 128 lb rail, 171 lb rail and 75 lb rail.

SS35 Screw Spikes: The Precision Anchor for Unshakeable Rail Track Stability The Ss35 screw spikes produced by Xinda have excellent anti-corrosion and anti-rust capabilities and long service life. We can produce according to drawings or samples, and the production process is strictly regulated in accordance with the ISO9001-2015 quality management system.

High-Performance Rail Spikes | Secure & Durable Railroad Track Fastening Solutions

Premium ASTM/EN-compliant railway spikes engineered for maximum track stability, safety & longevity. Ideal for mainlines, heavy haul, and industrial sidings. Request specs & pricing.

Premium Rail Fishplates | High-Strength Rail Joint Solutions for Track Integrity

Engineered ASTM/EN-compliant railway fishplates (joint bars) for seamless rail connections. Reduce maintenance, prevent misalignment & extend rail life. Get specs + quote.